These test rigs allow users to simulate realistic stresses, and represent shaft position and linkage as they would be in real drive shaft operations. These tests can be conducted under extreme torque and speed parameters. As a proven specialist for torque test rigs, aixACCT mechatronics offers systems tailor made to your requirements:

- 4-Square endurance test rig for four test specimens

- 2-Square high-torque test rig for service life testing

- 2-Square high-speed test rig for service life testing

-

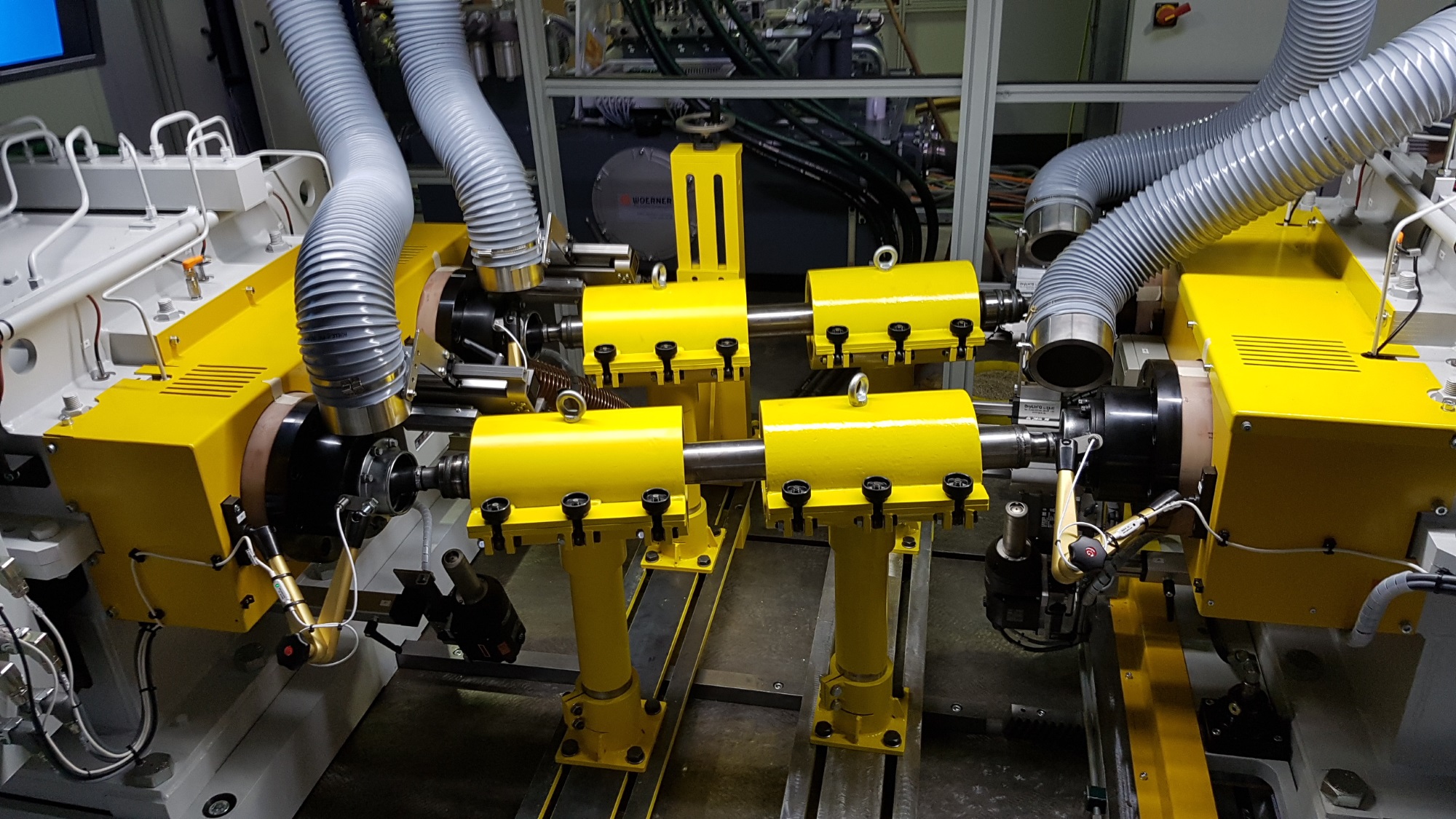

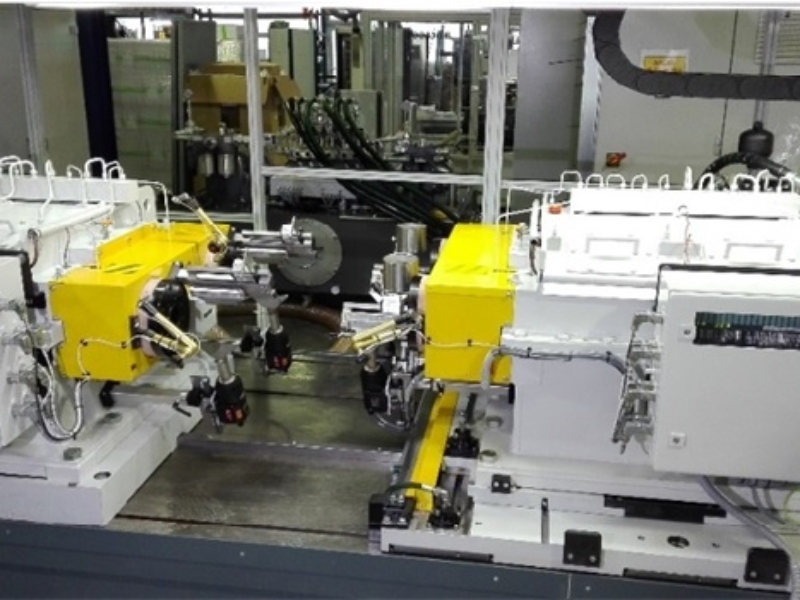

4-Square endurance test rig

The main components of this torque test rig are a pair of angle gears and a central unit for simulating deflections. The 4-Square can be driven either electrically or hydraulically.

Torque Up to 8,000 Nm

Electrically or hydraulically driven

Dynamic up to 600°/s

Corresponds up to approx. 22,500 Nm/s at 150 Nm/° rigidity per test specimenPower at specimen 200 - 500 kW Speed Up to 2,500 rpm

Dynamic 500 rpm/s

Pitch angle 0°-50°

± 35°

Dynamic up to 20°/sSpring deflection Up to +/- 300 mm

vmax = 2 m/s

Airflow simulation/cooling 0-30 m/s more as an option Joint temperature control RT-200°C Joint temperature monitoring RT-200°C Real-time capability Simulation of measured real-time driving profiles Torque

Up to 8,000 Nm

Electrically or hydraulically driven

Dynamic up to 600°/s

Corresponds up to approx. 22,500 Nm/s at 150 Nm/° rigidity per test specimen

Power at specimen

200 - 500 kW

Speed

Up to 2,500 rpm

Dynamic 500 rpm/s

Pitch angle

0°-50°

± 35°

Dynamic up to 20°/s

Spring deflection

Up to +/- 300 mm

vmax = 2 m/s

Airflow simulation/cooling

0-30 m/s more as an option

Joint temperature control

RT-200°C

Joint temperature monitoring

RT-200°C

Real-time capability

Simulation of measured real-time driving profiles

Additional features:

- Grease detection

- Axial force measurement

- Road data simulation

- Efficiency measurement

- Backlash measurement

The technical data is standard data and can be altered upon request.

-

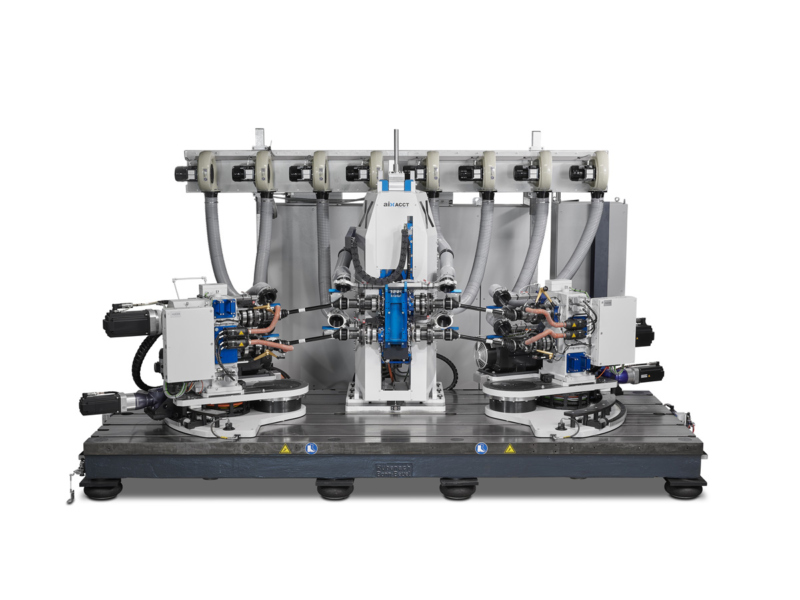

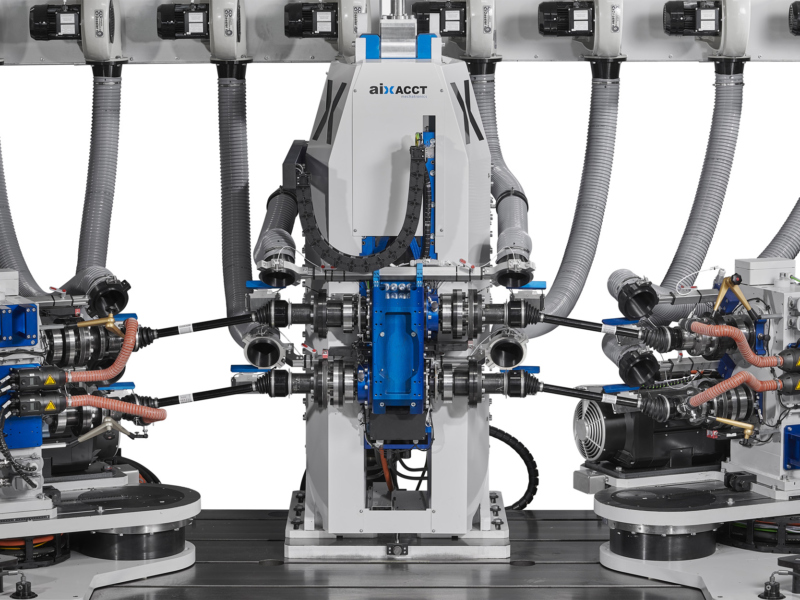

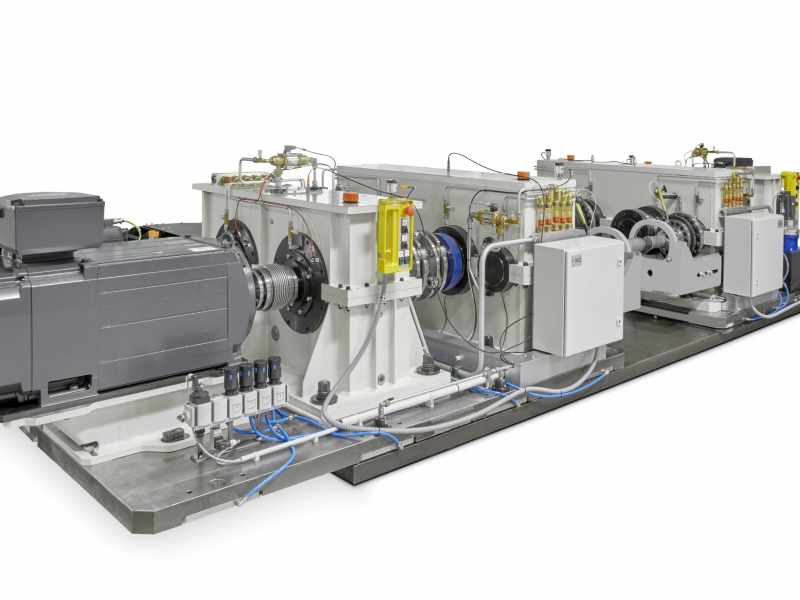

High-speed test rig for service life testing on side and drive shafts

Based on our experiences with the large 2 SQ test rig and its unique specification, we developed a faster and smaller 2 SQ test rig for one of our customers. Just like all our other test rigs, we included new functions and improved handling. We developed an automated alignment system, for example, that makes it easier to adjust the drive shafts.

The test rig allows users to simulate realistic stresses, and test shaft position and linkage as they would be in real drive shaft operations.

Torque Max. 5,000 Nm Speed Max. 6,500 rpm Power at specimen Up to 600 kW Swing angle torsion (hydraulic) 0 - 90° / ± 45° Radial displacement 0 - 400 mm Airflow simulation 0-30 m/s Joint temperature monitoring RT-200°C Clamping length 300 - 2,100 mm (CL-CL) or according to customer wishes Torque

Max. 5,000 Nm

Speed

Max. 6,500 rpm

Power at specimen

Up to 600 kW

Swing angle torsion (hydraulic)

0 - 90° / ± 45°

Radial displacement

0 - 400 mm

Airflow simulation

0-30 m/s

Joint temperature monitoring

RT-200°C

Clamping length

300 - 2,100 mm (CL-CL) or according to customer wishes

The technical data is standard data and can be altered upon request.

-

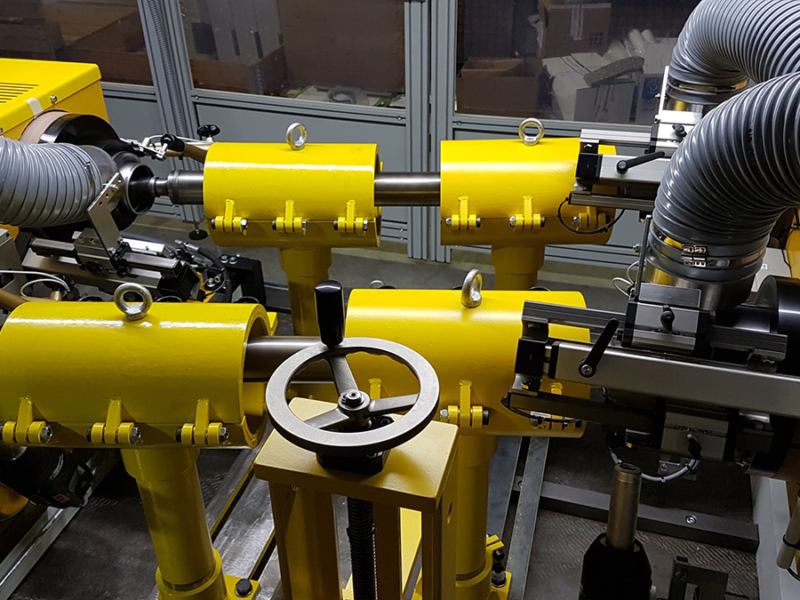

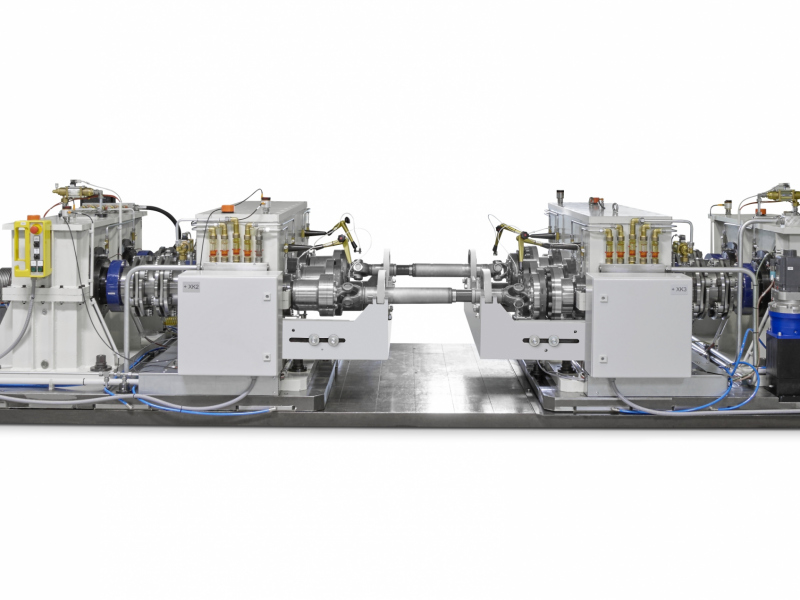

High-torque test rig for service life testing on side and drive shafts

This unique test rig is used for service life testing on drive shafts and cardan shafts. It allows users to simulate realistic stresses, and test shaft position and linkage as they would be in real drive shaft operations. These tests can be conducted under extreme torque and speed parameters.

Torque / speed a) Max. 30,000 Nm / max. 1,500 rpm

b) Max. 10,000 Nm / max. 4,500 rpm

Power at specimen Up to 850 kW Swing angle 0 - 180° / ± 90° Radial displacement 0 - 300 mm Airflow simulation 0-30 m/s Joint temperature monitoring RT-200°C Test specimen length 300 - 2,100 mm (CL-CL) or according to customer wishes Torque / speed

a) Max. 30,000 Nm / max. 1,500 rpm

b) Max. 10,000 Nm / max. 4,500 rpm

Power at specimen

Up to 850 kW

Swing angle

0 - 180° / ± 90°

Radial displacement

0 - 300 mm

Airflow simulation

0-30 m/s

Joint temperature monitoring

RT-200°C

Test specimen length

300 - 2,100 mm (CL-CL) or according to customer wishes

The technical data is standard data and can be altered upon request.